MAC Machines

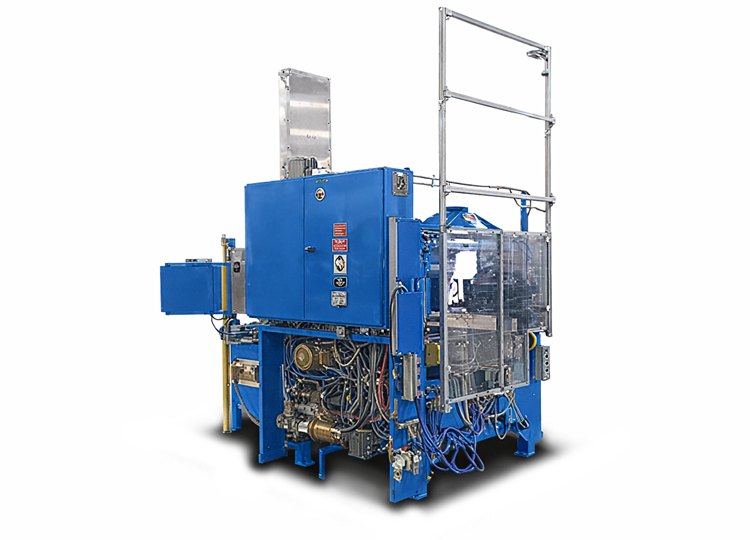

For decades, MAC has created custom-engineered solutions for energy storage manufacturers around the globe. Because consistent speed, reliability, safety, and sustainability are essential to your ROI and long-term success, we build those qualities into every machine that ships. Trust MAC to design and machine your custom battery manufacturing machinery. We don’t just do batteries though. Contact us and let’s put together a plan for your manufacturing needs.

MAC Machines

For decades, MAC has created custom-engineered solutions for energy storage manufacturers around the globe. Because consistent speed, reliability, safety, and sustainability are essential to your ROI and long-term success, we build those qualities into every machine that ships. Trust MAC to design and machine your custom battery manufacturing machinery. We don’t just do batteries though. Contact us and let’s put together a plan for your manufacturing needs.

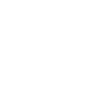

When preparing your pasted plates for battery assembly, you require machines that deliver rock-solid, consistent performance. From panel parters to manual brushing stations and automated options, MAC can design preparation and handling equipment that provides efficient labor and time-saving performance on the plant floor.

MAC offers a variety of Pasters, including Cotton or Steel Belt, and FOP, along with vacuum or mechanical Feeders, Parters, and Dividers. Our automation protocols help improve output, safety, and sustainability. From cast to continuous, antimony to pure lead, put MAC’s expert engineering team to work for you.

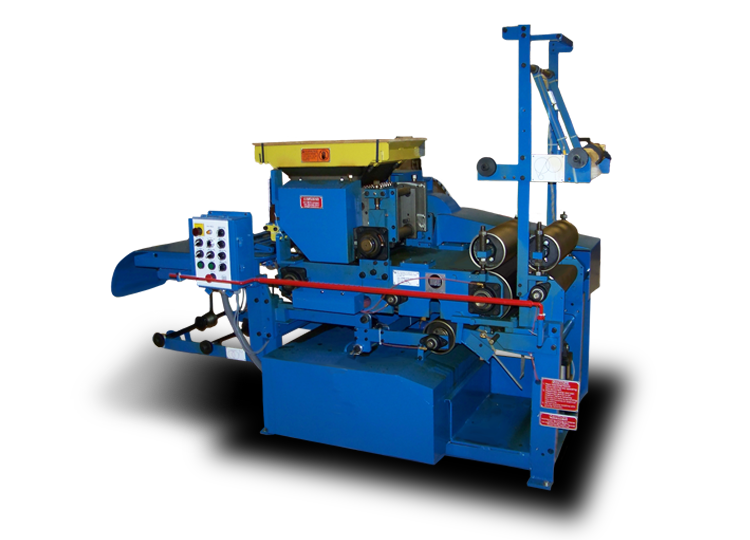

Searching for better plate drying uniformity and lower energy consumption? MAC’s line of Flash Dry Ovens performs. Our line includes multiple heated section lengths, but if you need custom lengths, just send us your product requirements and plant layout. Our engineers will get to work to meet those challenges head-on.

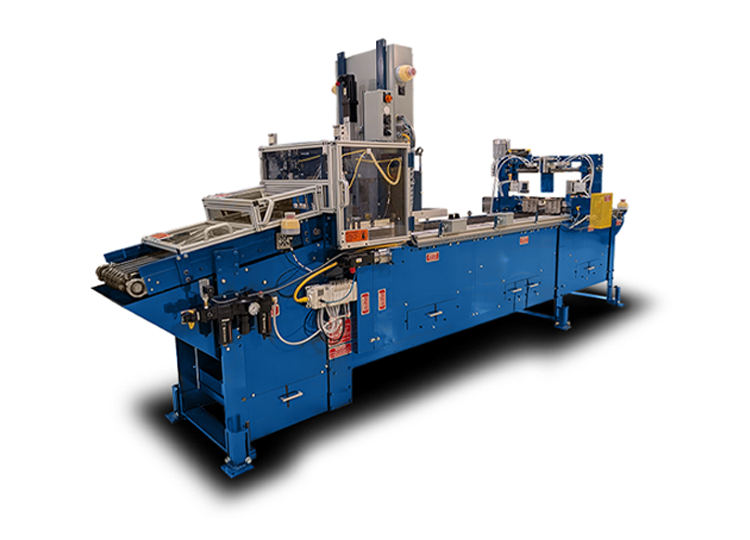

When it’s time to load your finished batteries onto pallets, MAC offers multiple high-speed stacking solutions that maximize your workforce, efficiency, and safety. We also offer several desirable options such as brushing, automatic offload, and pallet removal.

During the hydroset process, you want your plates to be ‘set-up’ and rigid enough to be machine-handled with minimum loss. That’s why accurately controlling the drying rate of freshly pasted plates is one of the essential steps in the battery manufacturing process. Customers have selected MAC’s line of curing chambers for precise control over time, temperature, humidity, and energy.

MAC offers various COS types to handle automotive, truck, AGM, and large industrial batteries. We offer In-Line, Rotary, Compression, Loading and Unloading, and many options to fit whatever you require from manual to automation processes.

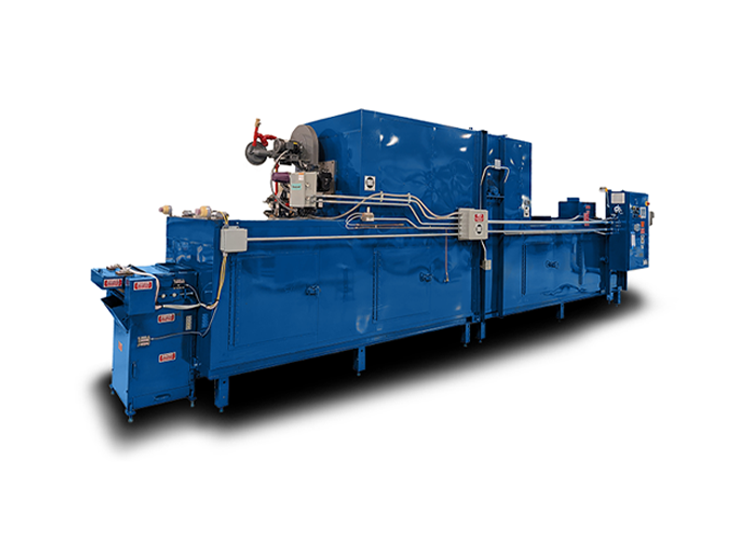

Accurate and efficient assembly of your batteries is critical to product quality and your company’s brand integrity. From acid fillers to engravers, and everything in between, MAC machines are designed to assemble your batteries accurately and efficiently.

When preparing your pasted plates for battery assembly, you require machines that deliver rock-solid, consistent performance. From panel parters to manual brushing stations and automated and robotic options, MAC can design prep and handling equipment that will provide efficient labor and time-saving performance on the plant floor.

MAC offers a variety of Pasters, including Cotton or Steel Belt, and FOP, along with vacuum or mechanical Feeders, Parters, and Dividers. Our automation protocols help improve output, safety, and sustainability. From cast to continuous, antimony to pure lead, put MAC’s expert engineering team to work for you.

Searching for better plate drying uniformity and lower energy consumption? MAC’s line of Flash Dry Ovens performs. Our line includes multiple heated section lengths, but if you need custom lengths, just send us your product requirements and plant layout. Our engineers will get to work to meet those challenges head-on.

When it’s time to load your finished batteries onto pallets, MAC offers multiple high-speed stacking solutions that maximize your workforce, efficiency, and safety. We also offer several desirable options such as brushing, automatic offload, and pallet removal.

During the hydroset process, you want your plates to be ‘set-up’ and rigid enough to be machine-handled with minimum loss. That’s why accurately controlling the drying rate of freshly pasted plates is one of the essential steps in the battery manufacturing process. Customers have selected MAC’s line of curing chambers for precise control over time, temperature, humidity, and energy.

MAC offers various COS types to handle automotive, truck, AGM, and large industrial batteries. We offer In-Line, Rotary, Compression, Loading and Unloading, and many options to fit whatever you require from manual to automation processes.

Accurate and efficient assembly of your batteries is critical to product quality and your company’s brand integrity. From acid fillers to engravers, and everything in between, MAC machines are designed to assemble your batteries accurately and efficiently.